In the realm of metal fabrication, where precision, durability, and efficiency are non-negotiable, hydraulic Tube end forming machines have solidified their position as indispensable tools for industries worldwide. From automotive and aerospace to HVAC, marine, and industrial machinery, these advanced systems redefine the standards for tube end processing—delivering consistent performance, versatile capabilities, and reliable results that meet the most stringent industry requirements. As manufacturing demands grow more complex, Hydraulic tube end forming machines continue to evolve, offering innovative solutions that streamline production workflows and elevate product quality.

At the core of hydraulic tube end forming machines’ appeal is their ability to deliver exceptional precision through hydraulic power. Unlike mechanical forming methods that rely on manual force or inconsistent pressure application, hydraulic systems use fluid pressure to generate uniform, controlled force across the tube surface. This ensures that tube ends—whether formed into flanges, beads, swages, expansions, or custom profiles—maintain tight dimensional tolerances, consistent wall thickness, and seamless connections to fittings, valves, or other components. For critical applications such as aerospace fuel lines, automotive brake systems, or industrial hydraulic tubing, this level of precision is mission-critical: it eliminates leak points, reduces the risk of system failures, and ensures compliance with global industry standards, including those set by aviation, automotive, and manufacturing regulatory bodies.

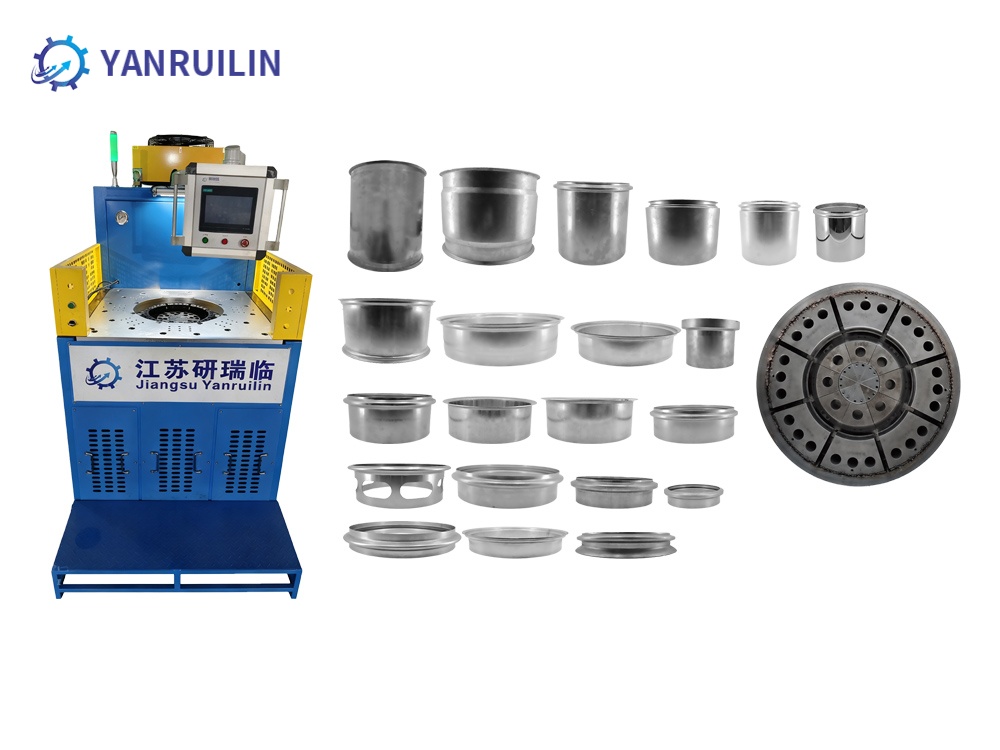

Versatility is another defining feature of hydraulic tube end forming machines, making them adaptable to a wide range of manufacturing needs. These machines can process diverse tube materials, from lightweight aluminum alloys and corrosion-resistant copper to high-strength stainless steel and titanium—catering to the unique requirements of different industries. Whether handling small-diameter tubes for medical devices or large-diameter, thick-walled tubes for industrial piping, hydraulic systems adjust to varying tube sizes, wall thicknesses, and forming requirements with minimal reconfiguration. This versatility eliminates the need for multiple specialized machines, streamlining production lines, reducing floor space usage, and enabling manufacturers to serve diverse customer demands without sacrificing efficiency.

Efficiency and productivity are key drivers behind the widespread adoption of hydraulic tube end forming machines. Equipped with powerful hydraulic drives and advanced control systems—including CNC (Computer Numerical Control) integration—these machines deliver fast cycle times, processing tube ends in seconds rather than minutes. Automated features such as programmable forming sequences, tool change reminders, and real-time process monitoring minimize human intervention, reduce the risk of error, and boost throughput. For high-volume production runs, this translates to significant gains in productivity: manufacturers can process hundreds or thousands of tubes per shift, meeting tight delivery deadlines and scaling operations to handle larger order volumes. Additionally, hydraulic machines are designed for durability, with robust construction and wear-resistant components that withstand the rigors of continuous industrial use, minimizing downtime and maintenance costs.

Safety and reliability are paramount in manufacturing environments, and hydraulic tube end forming machines excel in both areas. Modern systems incorporate comprehensive safety features, including protective guards, emergency stop buttons, pressure sensors, and overload protection, to prevent accidents and ensure operator safety. The sealed hydraulic systems also minimize the risk of contamination during forming, a critical advantage for applications where tube cleanliness is essential—such as medical tubing or food processing equipment. Furthermore, hydraulic forming processes preserve the structural integrity of the tube material by applying uniform force, reducing the risk of cracks, deformation, or material fatigue over time. This enhances the longevity and performance of the finished products, reducing warranty claims and improving customer satisfaction.

As industries embrace sustainability and cost optimization, hydraulic tube end forming machines offer additional benefits that align with these goals. By minimizing material waste through precise forming and reducing rework rates, these machines lower raw material costs and reduce environmental impact. Energy-efficient hydraulic systems also help manufacturers cut electricity consumption, contributing to greener operations and lower utility bills. Additionally, the long service life of hydraulic tube end forming machines—coupled with their low maintenance requirements—ensures a strong return on investment, making them a cost-effective choice for businesses of all sizes, from small fabricators to large-scale manufacturing facilities.

The evolution of hydraulic tube end forming machines continues to keep pace with emerging industry trends. Advancements in automation, such as integration with robotic arms for automated loading and unloading, and the adoption of IoT (Internet of Things) technology for remote monitoring and predictive maintenance, are further enhancing efficiency and reducing operational costs. These innovations allow manufacturers to optimize production processes, identify potential issues before they cause downtime, and make data-driven decisions to improve performance. As industries such as electric vehicles, renewable energy, and advanced aerospace continue to grow, hydraulic tube end forming machines are adapting to new materials and forming requirements, ensuring they remain essential tools for the next generation of manufacturing.

In summary, hydraulic tube end forming machines are more than just pieces of equipment—they are the backbone of precision tubing manufacturing. Their ability to deliver micron-level precision, versatile performance, efficient production, and reliable safety makes them indispensable across a wide range of industries. As manufacturing continues to evolve, these machines will remain at the forefront of innovation, enabling businesses to meet the demands of a competitive global market while maintaining the highest standards of quality and efficiency. For manufacturers seeking to elevate their tube processing capabilities, hydraulic tube end forming machines offer a proven, future-ready solution that drives success today and tomorrow.

Situs web ini menggunakan cookie untuk memastikan Anda mendapatkan pengalaman terbaik di situs web kami.

Komentar

(0)